3 reasons why insulated piercing connectors reduce transient resistance

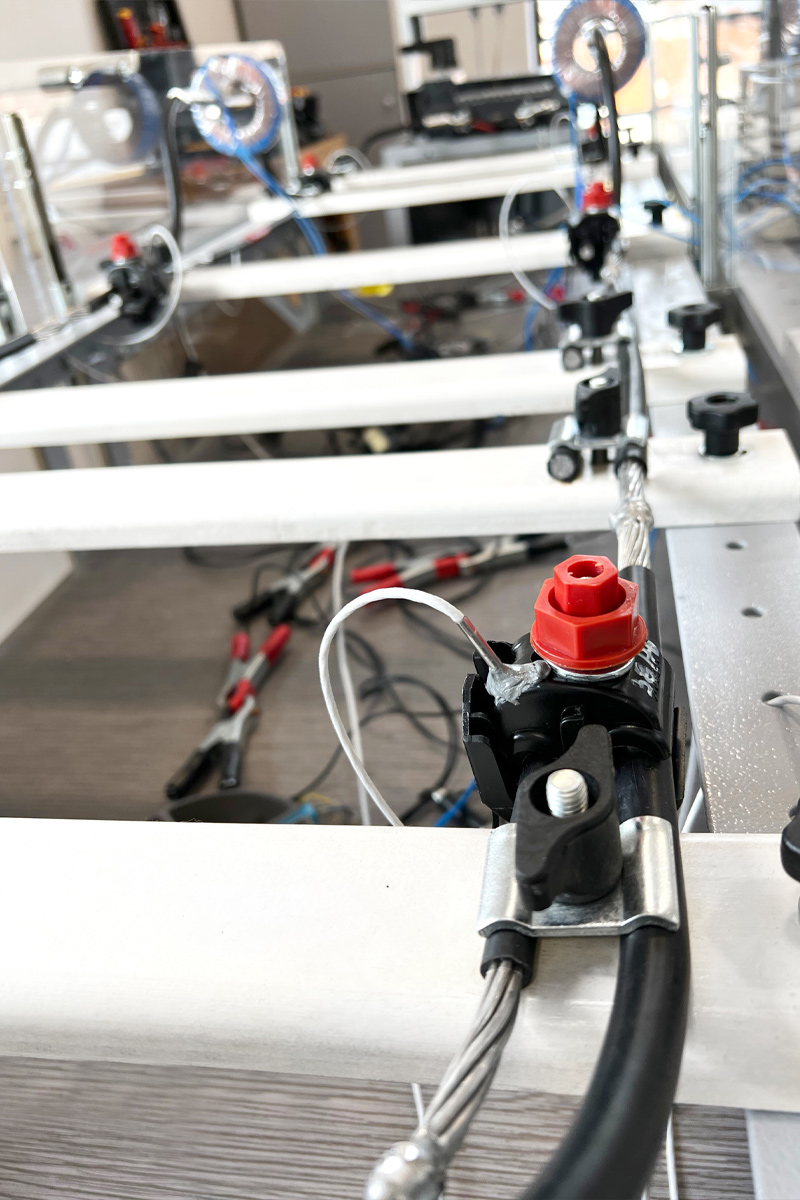

Marel IPCs are used to take a tap connection and three main applications are listed below:

to connect two LV ABC main lines - type CDR

to connect two LV ABC main lines - type CDR

to connect a LV ABC main line to a service line of a household - type CBS

to connect a LV ABC main line to a service line of a household - type CBS

to connect a LV ABC main line to a tap line of street light - type CES

to connect a LV ABC main line to a tap line of street light - type CES

In other words, they enable electric current to flow through the network without discontinuation. IPCs are popular because they are easy to install, no special tools are needed and one doesn’t have to strip the insulation from the cable, network remains insulated and safe from touch voltage after installation. Any heating on power distribution network is considered a loss. The most important thing is to enable secure and efficient connection with as few losses as possible. The flow of electric current is opposed by transient resistance that converts electrical energy into heat energy. Since the number of electricity distribution connections is large it is very important that losses are as minimum as possible.

Geometry and design of Marel IPC

How do we make energy efficient Marel IPC with very few losses on the network?

Design, geometry and kind of material of which contact plates are made are very important because it is the point of contact between the conductor and the connector. Kind of material is important because electrical resistance of the connector itself depends on it as well as the energy required for the electrons to pass from the conductor to the contact plate and then come out of it. Design and geometry of contact plates are important because they affect the depth of penetration of contact plates into the conductor. They also have great influence on the energy required for electrons to move, especially when they pass from the conductor to the contact plates and then come out of them.

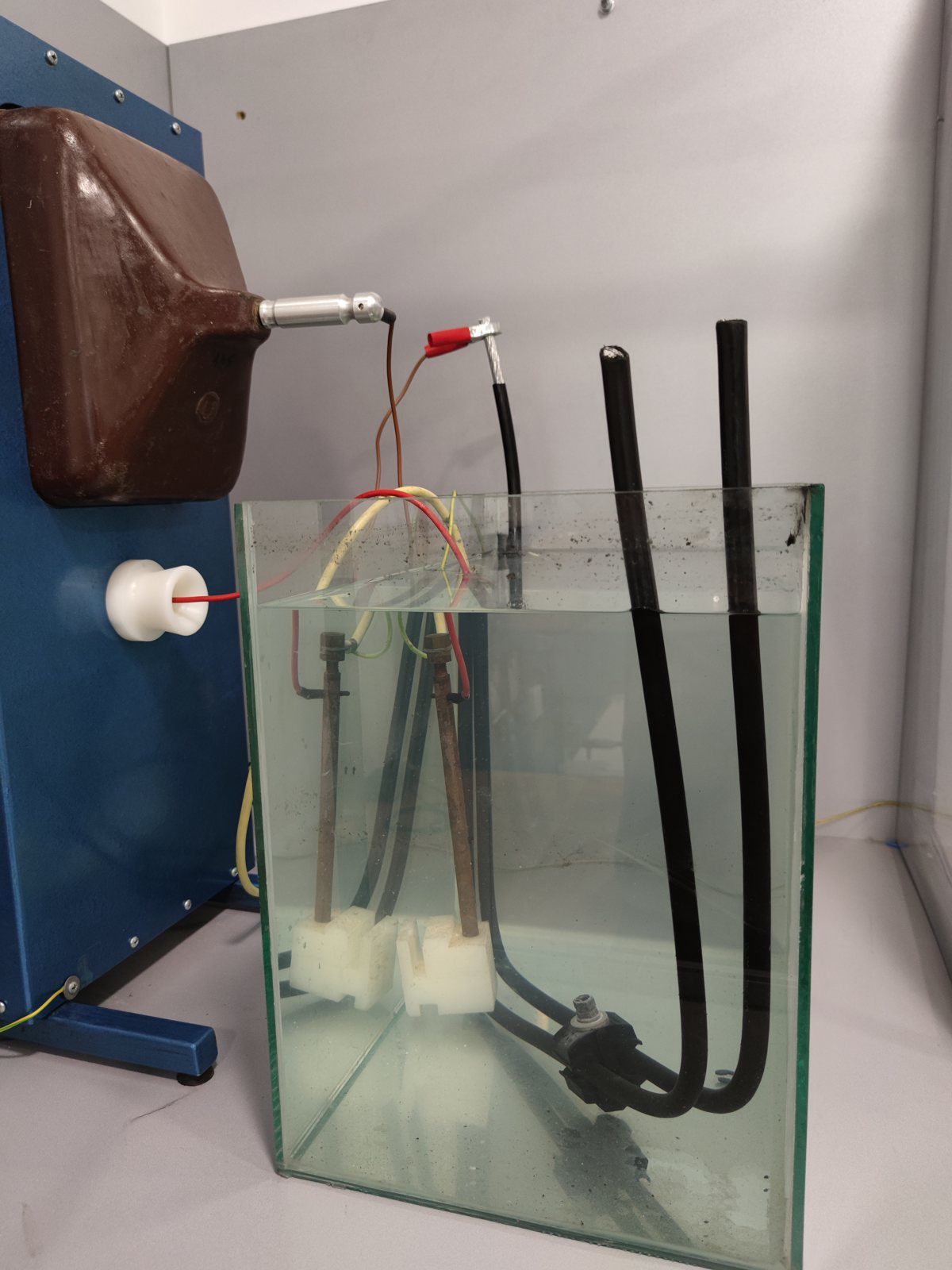

Marel Waterproof Insulated Piercing Connectors

It is very important that there is no moisture at the contact points, no matter how much time has passed since the installation. Moisture at the contact point leads to electrolytic corrosion in the case of joint of copper and aluminum, or leads to aluminum oxidation in the case of joint of two aluminum conductors. Both chemical processes greatly increase transient resistance at the contact points and lead to immense heating. Marel IPC connectors are designed in such a way that, thanks to a number of technical details, they do not allow moisture to seep in. In addition, they are protected with electrical contact grease. We always emphasize that after installation of Marel IPC connectors it is necessary to place end caps on the ends of branch conductors to prevent moisture from reaching the contact point through the conductor.

Easy installation

In order to reach a high coefficient of efficiency of the connector it is important that the installation is easy regardless of the conditions that prevail when working in the field and working at height. Marel IPC connector has a number of implemented technical details that allow it to be easily mounted on conductors, to achieve good connection by simple tightening and that after installation and regardless of weather conditions it does not have to be additionally tightened, i.e. the connection does not need correction. Marel IPC can be installed at temperatures from -22 to +45 degrees Celsius. Installation was tested and allowed even at -50 degrees Celsius, although the insulation on ABC itself then becomes 45% harder.

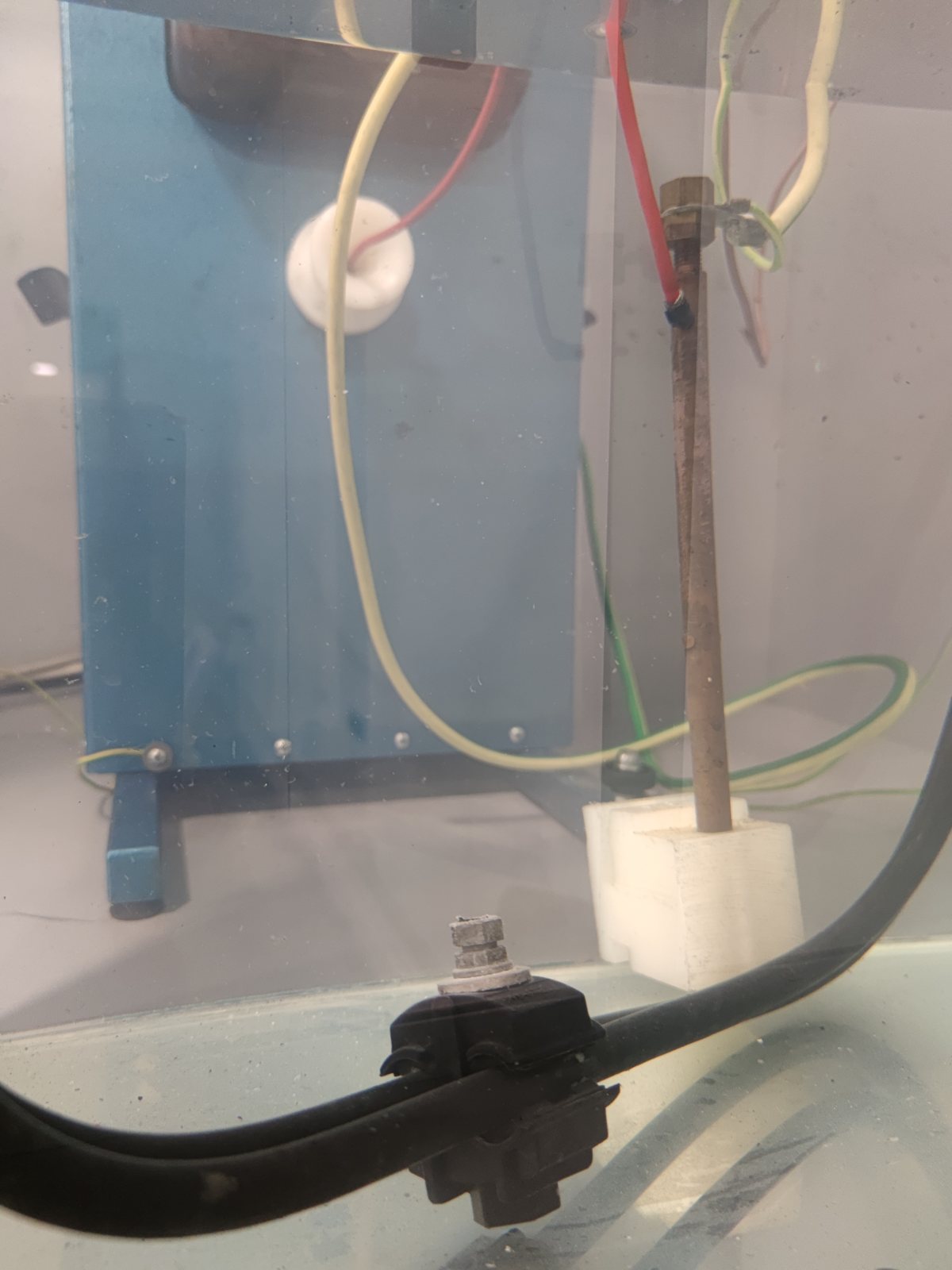

Routine testing

It is important to constantly check and reconsider the results and then an excellent connector becomes even better. We strive for electrical losses on our connector to be zero. Marel IPC is exposed to numerous tests that result from standards EN 50483 and NFC 33020 and to numerous factory tests that we've developed. The following video shows transient resistance of 5.4 μΩ, which is one of the best results among world competition. Minimum transient resistance results in less losses on the network due to efficiency of our IPC, which is one of our main goals that we actively work on.