Importance of proper installation – example from everyday practice:

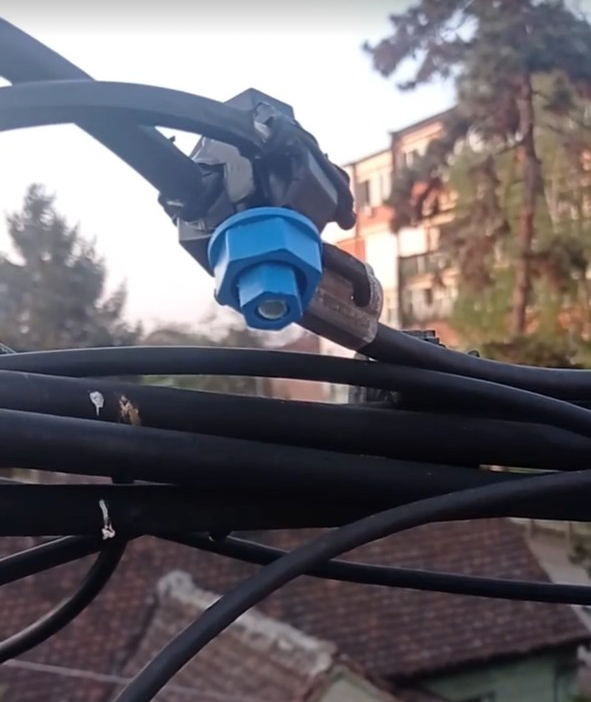

Important note - the connector with the blue shear-off nut is a Marel insulated piercing connector type CES, other equipment is of unknown origin. Location - Republic of Serbia. The phenomenon of incorrect installation most often comes from insufficient training of employees, excessive self-confidence acquired on the basis of practice that was not accompanied by the acquisition of new knowledge in the field of installation and development of modern equipment. Very often the practice that has been applied for years has been wrong and therefore the experiences gained in that way are wrong.

With the progress of technology in the field of connection, branching and junction of overhead insulated lines, there was a need for new knowledge and active exchange of experiences and cognitions between equipment manufacturers and persons engaged in training the employees engaged in construction of overhead insulated networks.

Attached we have a Marel insulated piercing connector type CES recognizable by a blue shear-off nut that is still working despite the fact that three major mistakes were made during installation:

- First: the clamp selection is wrong. Marel IPC connector with a blue shear-off nut is declared as 16-95 / 1.5-10mm2. The range of the main line is from 16 to 95mm2 Al or Cu - the conductor on which the connector in this case is installed is 35mm2 and it is correct, the range of the tap-off line is from 1.5 to 10mm2 Al or Cu - the conductor on which the connector in this case is installed is Al 16mm2 and this is wrong because that conductor goes out of the designed range. This connector is primarily intended for the connection of street lighting and not for network connection, which was done in this case. Although it is loaded maybe 60% more than the allowed, Marel clamp it still working normally, and we as manufacturers are very proud of that fact.

- Second: Manufacturers are required by standard EN 50483, which refers to insulated piercing connectors, to deliver them with shear-off nuts. These shear-off nuts must break when sufficient tightening force is achieved. As it can be seen in the attachment, the blue nut on Marel connector type CES is still undamaged, which means that it still contains the part that should have been sheared off during installation, which leads to the conclusion that in this case the connector has not been tightened enough. Tightening torque of blue shear-off nuts is 10-11Nm. So Marel connector, although not tightened enough, works even at perhaps 60% higher load. When the connectors of this type are not tightened enough they have increased transient resistance and thus increased heating, i.e. increased losses at the point of contact by transforming electrical into thermal energy.

- Third: The attachment shows that the insulation was removed from the branch conductor, which is also a very big mistake which makes the entire system of insulated connectors meaningless. By removing the insulation, the employee who performed the installation allowed moisture to penetrate into the contact points, as well as the penetration of moisture into the conductor of the aerial bundled cable. The real service life of the connectors is about 35 years and more, but when the insulation is removed moisture is allowed to reach the contact point, which after a certain period of time, like three or more years, leads to appearance of electrolytic corrosion between contact plates and conductor and consequently to a significant increase in transient resistance, which can cause a number of technical problems, ignition of the clamp, interruption at the contact point, etc. The penetration of moisture into ABC conductors leads to another technical problem - the occurrence of oxidation of aluminum inside the conductor, which leads to heating of the conductor, increased losses and makes it difficult to install new connectors on such conductors because contact points receive moisture from inside the conductor.

The motive for stripping the insulation from the conductors is very interesting. The person who installs the connector very often removes the insulation because, according to their own belief, they establish better contact in that way. It is most often a result of poor training or negative business practice. The same person had previously chosen the wrong type of connector and installed a connector that should supply electricity to a public lighting lamp in the place from which a building is powered. After the wrong choice, there was also wrong installation, Marel connector was insufficiently tightened, and a 60% bigger conductor than allowed was placed in it. The motive for stripping the insulation was to achieve better contact and from the above we can see that the contact that was made has a lot of technical shortcomings.

We often hear that removal of insulation from insulated aerial bundled cables is used especially on neutral conductor, because in case that there is an interruption in the contact point it leads to major breakdowns in the building that is the subject of connection. Apart from great importance of good selection of high-quality and well-dimensioned connectors, it is very important that those employed at these jobs are serious Wiremen.

We are proud of Marel connectors which, in addition to operating at temperatures from -40 degrees Celsius to +80 degrees Celsius, to which in the summer black surfaces can be heated in the sun, correct very serious installation errors. It is very important that the connectors are installed by trained Wiremen who follow the installation instructions and the manufacturer's recommendations.